Why are Tesla hubcaps completely different from traditional car hubcaps?

With the continuous popularity of new energy vehicles, there are more and more pure electric new energy vehicles on the road. In first-tier cities, almost half of the roads are new energy vehicles. Rapid development and comprehensive innovation make the new energy market more colorful.

Careful friends have discovered that the wheels of many pure electric models are peculiar in appearance, with fewer hollow parts, which are completely different from traditional car wheels. Why is this? Is it just to make new energy models look more futuristic Do you feel it?

Take the Tesla model 3 as an example, you will find that most of the long-life version of the model 3 on the road have a layer of spoiler on the outer ring of the wheel hub. It will feel very inconsistent, but this is indeed the shape often used by most new energy vehicles.

In addition to some aesthetic factors, the more important thing is that this design can bring good low wind resistance. To know the driving characteristics of pure electric vehicles, when the vehicle is running at a constant speed, all the work done by the motor is used to offset the friction force and air resistance of the tires. Since the friction force of the tires is calibrated at the factory, the battery capacity is fixed and the only The choice is to put more effort into aerodynamics.

The smaller the wind resistance, the more power saving the motor, and the longer the battery life.

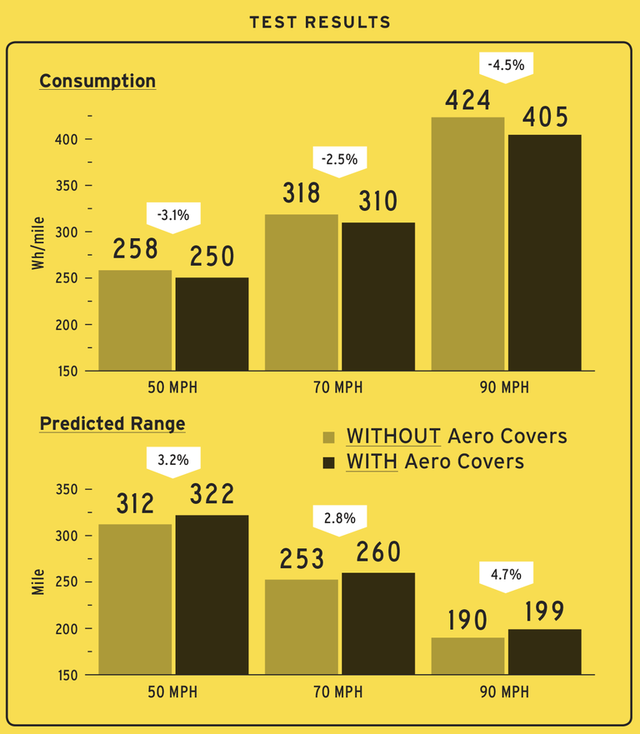

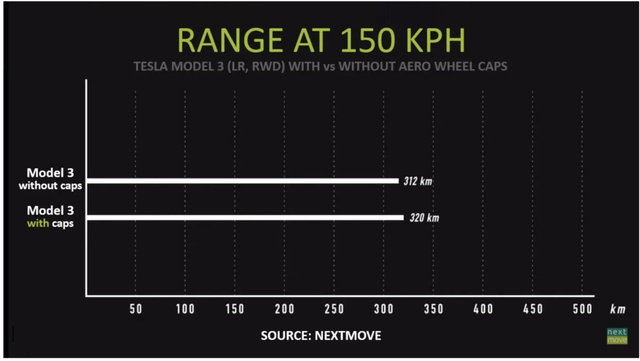

In a professional test conducted by professional automotive media "Car and Driver", at 50, 70 and 90 mph, the Model 3 with the hubcap installed increased the cruising range by an average of 3.4% compared with the non-installed model. The difference is most pronounced at 90 mph, a 4.5 percent improvement, or 10 miles. Professional editors were stunned by the results, "Aerodynamic wheel covers are a considerable advance in the automotive world, not as effective as a continuously variable transmission or low rolling resistance tires."

In the automotive industry, it requires a very high cost to improve the aerodynamics of the whole vehicle and reduce the wind resistance, and this plastic hub cover can be exchanged for high profits at a very low cost, which is also a difference between cost, efficiency and appearance. Clever compromise.

Robert Perrin, head of Tesla's aerodynamics department, has revealed some secrets of aerodynamic hubcaps: "In urban environments, low rolling resistance tires play a greater role. In high-speed environments, hubcaps have a greater impact on aerodynamic efficiency. It’s great, and it works wonders when used smartly.”

Do you think this is specially developed by car companies for new energy models? Of course not, this thing has been applied in the race against time for a long time!

The same type of hubcap for the world's top F1 races

As early as 2006, the Ferrari F1 team took the lead in using the hubcap design, which directly attached a carbon fiber disc to the rear wheel, leaving only the hole in the middle to facilitate the disassembly and assembly of the hub. Then it was reported directly by the McLaren team, but it turned out that in the 2006 Turkish Grand Prix, Toyota and Red Bull directly copied Ferrari, and almost all teams used this design after that. Because as early as 1993, a study said that this kind of hubcap can reduce air resistance by 2.5%.

In 2007, the Ferrari F1 team added a cover to the front wheel, this time it was a little different, because the cover of the front wheel was separated from the wheel, so it did not rotate with the wheel. And BBS very thoughtfully painted the shape of the hub on the cover, and the front wheel gives the illusion of suspension.

In 2009, some teams "crazy" developed a front wheel hub cover with air intake holes, which can use the collision wind to air-cool the front wheel's braking system. However, this design was discontinued in 2010 due to security risks. So the engineers of F1 opened their minds...

In 2010, engineers created the "concentrator ring" hub, which works by extracting hot air from the braked components, thereby reducing the effect of the external cooler's rearward airflow, reducing turbulence and improving the car's performance. aerodynamic performance. This shape is still in use today, appearing on Mercedes-Benz's pure electric models and OZ modified brand wheels...

2022 is a year of great changes for tires in the history of F1. In 2022, the inner diameter of the tires of F1 cars will be increased from 13 inches to 18 inches. Larger wheels will inevitably cause a wider range of turbulence. In order to reduce turbulence and better follow the car, the rear car can more easily use the clean air to overtake the front car, the new regulations have introduced a solution for the hubcap.

The F1 front wheel hubcap mentioned above was also used by McLaren on its Ultimate Series sports car Speedtail, which is also the fastest model ever produced by McLaren. Its front wheel It is also equipped with a hub cover made of carbon fiber, which is used to reduce the turbulence generated by the front wheel at high speed and further reduce the wind resistance. This cover does not rotate with the wheel, but remains relatively stationary.

The operation of covering the spokes of the hub to reduce wind resistance is not only available on cars, but also on professional bicycles.

On professional track bicycles, it can also be found that many riders use closed wheels. The whole wheel is like a "big cake". The advantage of closed wheels is to reduce the turbulence of the spokes in the air resistance of the bicycle, which is more conducive to reducing the air resistance, making the car go faster.

Post time:Sep-09-2022