TPE interior parts have made a major breakthrough in the field of automotive applications

With the development of society and the continuous exploration in the field of materials, the advent of composite materials has gradually replaced traditional metal materials in many aspects. The deficiencies of traditional metal materials meet the special needs of different customers. In particular, the rise of the new energy vehicle industry has created more application scenarios for lightweight composite materials.

In the early promotion of automotive lightweighting, thermosetting composite materials were first used. In recent years, thermoplastic composite materials have gradually entered the market, and the market demand is increasing year by year due to the reduction in cost while reducing quality. The free selectivity of thermoplastic composite properties is very large, and its physical properties, mechanical properties, chemical properties, etc. can be freely changed through different materials and matching ratios. At the same time, thermoplastic composite materials also have the advantages of good recyclability, recyclability and reuse, which are more in line with the environmental requirements of low carbon and environmental protection.

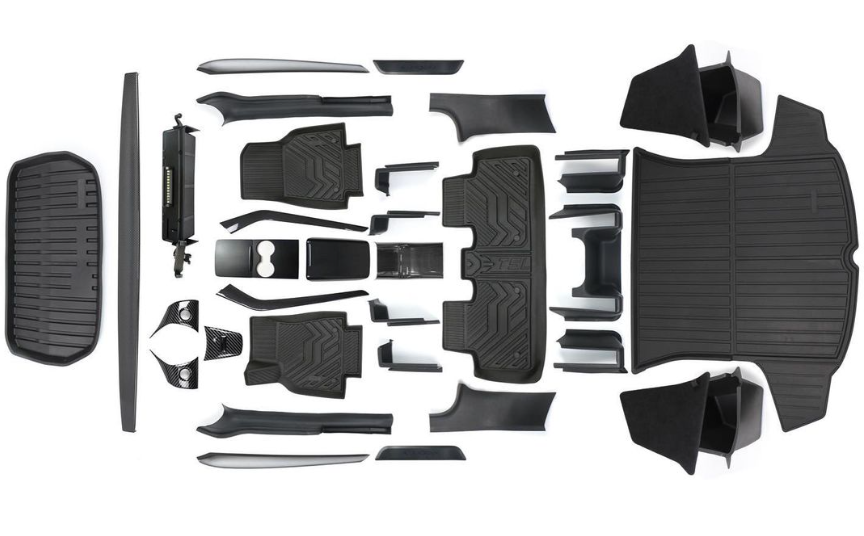

Recently, there have been increasing inquiries and demands for thermoplastic composite automotive interior and exterior trim. In response to the market and customers, special research has been carried out on the molding process of thermoplastic materials.

In the process research of thermoplastic materials, we use a variety of composite materials with different textures, which makes the texture selection of thermoplastic composite materials more diverse when making appearance parts. The product adopts one-shot molding by injection molding, which greatly shortens the production cycle of the product. The back of the product can be formed with various assembly structures to meet different assembly requirements.

The production process of the product is:

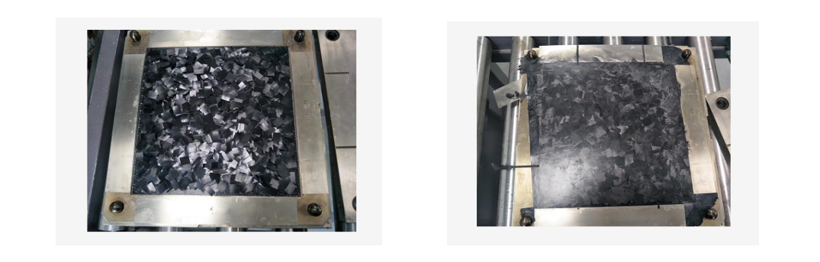

1. Plate production: cut according to size. After the cutting is completed, the amount of material is calculated according to the size of the sheet, and the material is evenly spread on the flat die to be pressed to make the sheet.

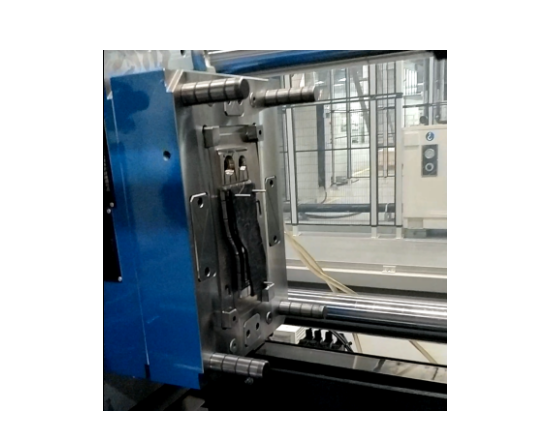

2. Molding and injection molding into an integrated type: Cut the manufactured sheet according to the shape and size of the composite part of the product, and the cut sheet is deheated in an infrared rapid heating furnace until softened and transferred to an injection mold for molding-injection molding .

3. Surface painting treatment.

Products can also be made from recycled carbon fiber. The recycled carbon fibers are first made into the form of carbon felt for recycling, then molded into sheets, and finally molded by injection molding. Thermoplastic composites offer more texture design options for automotive interior and exterior trims.

We have all kinds of advanced equipment required for raw material plate making, plate and product machining, compression molding and injection molding. In the future, we will continue to devote ourselves to the research and development and innovation of thermoplastic composite materials in the application of automotive interior and exterior decoration, and provide customers with more choices of materials and manufacturing processes to meet the needs of the automotive industry.

Post time:Jul-22-2022