The application of 3D scanning in the automobile modification industry

After years of development, the car has become more than just a means of transportation. The development direction of automobiles will be intelligence, comfort, personalization, energy saving and environmental protection. Among them, the personalized requirements have given birth to the development of the car modification industry.

Automobile modification is a kind of culture, and it is also a necessary stage in the development of automobile history. With the large-scale industrialization of the automobile industry, the high concentration of global parts supply, and the obvious homogeneity of automobile technology and manufacturing, the modification is to meet the needs of car owners. For the individual needs of cars, while pursuing performance, some people who have a special sense of fashion or car styling have begun to turn their attention to the shape of the car. 3D scanning provides strong technical support in the modification of car shape.

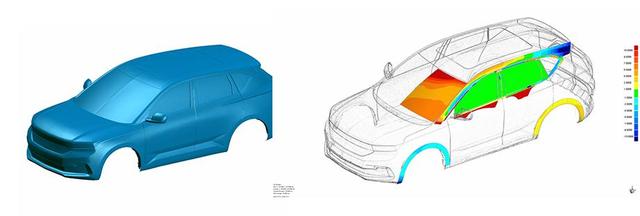

Vehicle 3D Scanning

3D scanning mainly uses laser 3D scanners in car modification. 3D laser scanning technology uses the principle of laser ranging, and can quickly reconstruct the information by recording the 3D coordinates, reflectivity and texture of a large number of dense points on the surface of the measured object. The three-dimensional model of the measured target and various data such as line, surface, and volume. Since the 3D laser scanning system can obtain a large number of data points of the target object intensively, compared with the traditional single-point measurement, the 3D laser scanning technology is also known as a revolutionary technological breakthrough from single-point measurement to surface measurement.

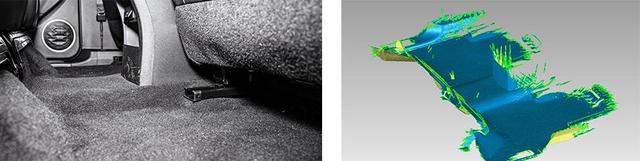

3D scanning of interior parts

Using 3D scanning to obtain the appearance size and structural size of the car provides a basis for car modification, which can ensure that the designed data does not interfere with other parts and there is no gap, thus ensuring the quality and accuracy of the car modification.

3D scanning of wheel hub

The specific process of 3D scanning in car modification: carry out 3D scanning on a certain part, denoise and straighten the point cloud. Use design x/ug/catia to import point cloud for reverse design and optimization design. After the simulation verification is passed, 3D printing or cnc or mold is used for production, and then the surface treatment includes grinding and painting, electroplating, water transfer printing, etc. Finally install. If there are defects in the structure or appearance in some places, it can be fine-tuned.

3D scanning of car floor mats

Post time:Jul-29-2022