Tesla Super Pipeline Evolution History

Tesla's fate has not been optimistic. In 2015, the former chairman of Daimler commented that Tesla couldn't even build the doors well and could not be compared with the great German car company. Seven years later, Tesla's achievements are indisputable. It has 4 car factories around the world and is capable of producing nearly 2 million cars a year.

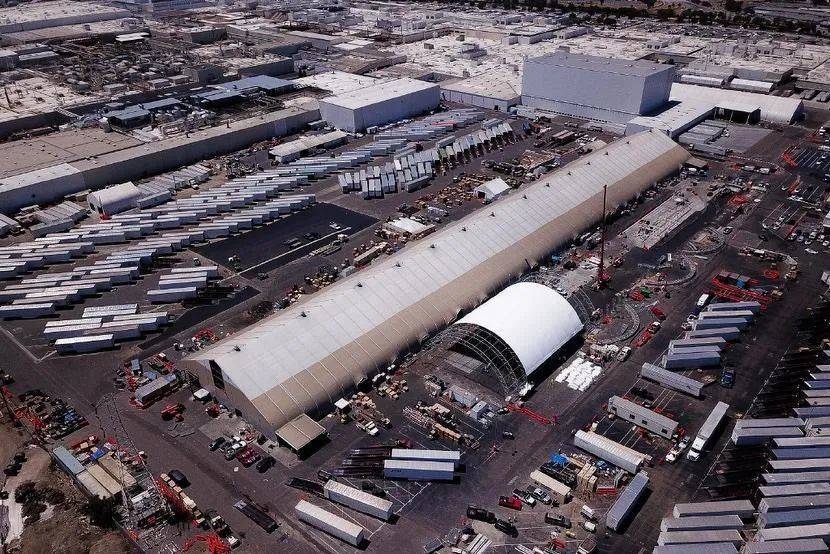

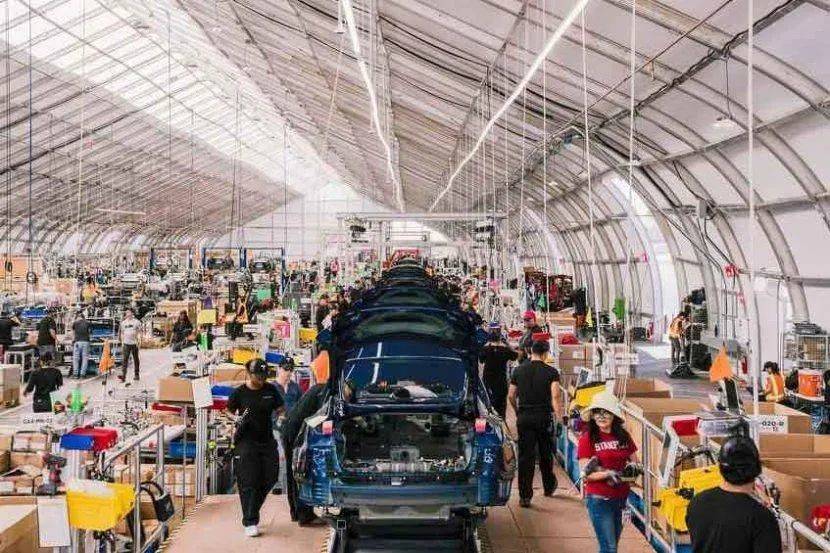

Behind this change, the turning point occurred in the spring of 2018, when Tesla erected a large tent in the vacant lot of its first car factory, Fremont, California, to assemble the Model 3. Tesla forged the prototype of the future Gigafactory. A set of production ideas and practices that are different from the traditional automobile industry have been explored from scratch, with self-developed automation equipment, complex software systems and innovative processes.

The ultimate pursuit of production efficiency and capability also explains Tesla's unique product design and the resulting high gross profit. Tesla has been working on reducing auto parts for years, which can streamline production steps, shorten production time, and reduce manufacturing costs. Model 3 deliveries began in 2017 with just over 10,000 parts, a third of the Model S delivered in 2012.a

The hardest product is not the car, but the factory that makes the car

"The hardest part is not designing the Model T, but discovering the Ford assembly line and building the Rouge River factory." In an earnings call in 2017, Musk said that Tesla treats the factory as a product , a machine that makes machines.

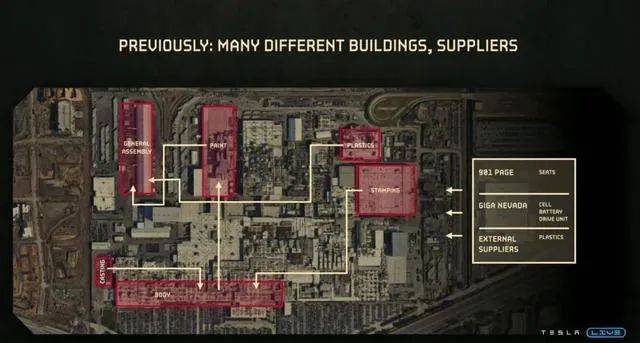

Tesla’s factory exploration began with the purchase of the Fremont, California factory from GM and Toyota in 2010. Since then, Tesla has successively established the Nevada battery factory, the Shanghai Gigafactory, the Berlin factory, and the Austin, Texas factory.

A key turning point in Tesla's factory evolution is the Model 3 deliveries from 2017 to 2019. This is also a time when Tesla is stuck in capacity hell.

When the Model 3 was released in early 2016, Tesla planned to start mass production on a small scale and then ramp up to 5,000 units per week. But skyrocketing orders have led Musk to advance Model 3 deliveries from late 2017 to July 2017, hoping to build a highly automated, worker-free assembly line to speed up production.

Before 2018, Musk wanted to automate by purchasing off-the-shelf robotic arms, AGVs (mobile robots that can transport materials in the production line) and other equipment, with poor results.

At the California factory, by the summer of 2017 engineers were teaching robots to recognize and grab wires of different colors. At the Nevada battery factory, robots are far less precise and faster than humans when they drain thousands of batteries into battery packs. Tesla had to seconded dozens of workers to Panasonic to manually assemble the battery packs. In the fourth quarter of 2017, Tesla produced only 2,425 Model 3s.

The bigger difficulty in automating the production of Model 3 is that Model 3 changes frequently. Musk hopes that the production line can also keep up with product iterations in a timely manner, which means that the production line must be very flexible and can quickly adapt to new parts and changing processes.

The manufacturing methods of traditional car companies cannot meet the requirements. In the original assembly line, only one fixed process was repeated for each process, and the goal of automation equipment such as robotic arms was to complete a single step quickly and accurately, rather than adapt to changes.

In mid-2017, Musk changed his mind and started recruiting more "laymen." Allen Chih Lun Pan, an engineer who worked on intelligent driving at GM, joined Tesla's factory team at that time. Allen was 33 years old at the time and came from Taiwan, China, and preferred fields such as robotics and autonomous driving that Musk called "Physical AI". Compared with the technicians Tesla recruited in the past with years of experience in car production, Pan and a group of new entrants at the time were young and inexperienced in production.

That's exactly what Musk is looking for. "You don't have the old production concept of the auto industry in your head, you can solve the problem with another kind of cognition." Musk said when recruiting Allen.

Half a year later, Musk wrote an all-staff email in April 2018, asking all R&D personnel not directly related to Model 3 to go to the factory to help. Tesla began a far-reaching event at this time, building the GA 4.

GA, General Assembly, is the final assembly line. Previously, the California factory had a total of 3 final assembly lines, of which GA 3 was responsible for the production of Model 3.

Unlike the first three lines, the GA 4 is housed in a semi-permanent enclosed "marquee." It has long been derided as a "vegetable greenhouse" by the outside world, a testament to Tesla's stretched production capacity.

Musk is well aware of the importance of manufacturing capabilities. He said in Tesla's Q3 earnings call in 2017: The essence of manufacturing competition is the competition of manufacturing capabilities, that is, the competition of factories.

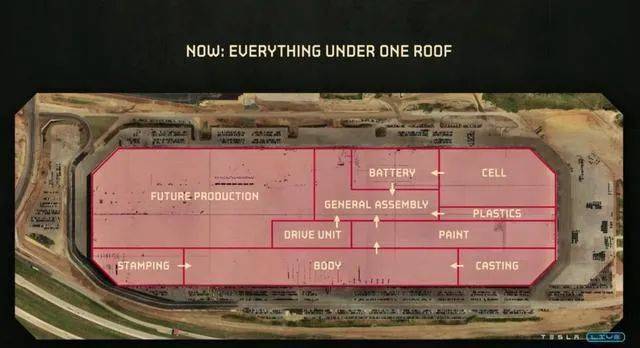

The Shanghai factory also shows another thread of Tesla’s factory evolution: the ultimate pursuit of improving space utilization efficiency and compressing logistics time.

The layout of Tesla's California factory follows the traditional car factory: stamping, assembly, spraying, and final assembly. These four major automobile manufacturing links each have independent factories and are scattered around the factory. In the Shanghai factory, these four processes are all integrated into a super-large factory building covering an area of 80 hectares, which is equivalent to 110 standard football fields. Each link in the workshop adopts a double-layer or multi-layer structure, the upper layer is used for component manufacturing, and the lower layer is used for component transportation. Not only the pursuit of plane space efficiency, but also the pursuit of three-dimensional space efficiency.

There are more than 100 crossings in the Shanghai factory. When the container trucks transporting parts and components enter the factory, they will stop directly at these crossings, the container door will be opened, and the parts will enter the production line directly from the container, eliminating the need for unloading and parts entering. The time required for warehouse, delivery, and production line also saves a batch of warehouses, and containers are temporary warehouses.

Based on the experience of the Shanghai factory, Tesla has “produced” the Berlin factory in Germany and the Austin factory in Texas in the last two years. Together, they will serve Tesla's ambitious goal of producing 20 million vehicles a year in the future, a figure close to China's total passenger car sales last year (21.48 million).

Looking back at Tesla's journey out of capacity hell is an uncompromising victory. If the idea of rapidly iterating the production line to follow the Model 3 was abandoned, Tesla’s factory could use more of the legacy of its predecessors to meet the standards faster, but it insisted on doing great in its own way. They are not filling the current hole, but accumulating long-term assets and building a deep enough moat with enough research and development.

Post time:Jul-08-2022